General information

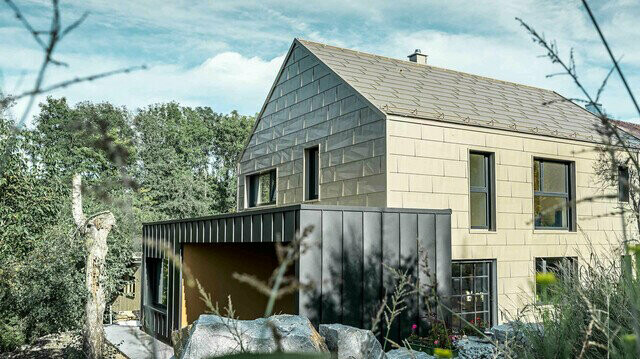

With uncoated aluminium strips, the natural, rolled texture of the substrate material creates an attractive surface appearance. Due to the different rolling processes that substrate material can go through during production, the appearance of the rolled texture is not always uniform. When installing and working with aluminium, use components from the same load or delivery, and pay attention to the laying direction in order to achieve an appearance which is as consistent as possible. When using uncoated aluminium strips, it is unlikely that you will obtain a uniform appearance as can be achieved with colour-coated aluminium strips.

Storage and transport

The goods should be stored in a covered and dry area. Avoid storage in damp areas. The stored goods should be protected from alkaline influences (mortar, concrete, limestone, cement dust, etc.) and from lyes, acid fumes and salts (e.g. road salt). In the case of tightly packaged aluminium parts or wrapped aluminium strips, it should be noted that oxidation caused by water (e.g. condensation or rain water) can occur in the form of black or white spots. This will not affect the durability of the product as long as other chemical influences do not cause the aluminium to degrade further. However, it can significantly impair the visual effect. Short-term storage (less than two weeks) in the open air is possible as long as the stored goods are protected from rain, condensation and splash water with an appropriate air-permeable cover. Note: the manufacturer's packaging is only designed to provide protection during transport.

Machining and processing

When profiling, rounding or folding uncoated aluminium strips into standing seams or double-lock standing seams, observe the guidelines in the Prefalz installation instructions. Uncoated aluminium is extremely sensitive to scratching and this must be taken into account during machining and processing. Although scratches do not impair the durability of the material, they can impair the surface appearance. When processing and installing uncoated aluminium, sweat from your hands can cause marks due to oxidation of the aluminium surface. This can cause prints and spots which are extremely difficult to remove. Wearing gloves when working with the material can reduce this effect. Uncoated aluminium has a natural surface which changes slowly and unevenly depending on environmental influences. Note: uncoated aluminium is particularly good at reflecting light. If you do not want your façade cladding or roof covering to reflect light, coil-coated, use components with a matt surface.