How PREFA siding.X made the new construction of a high-rise building in Erftstadt from the 70s look modern and timeless – not just now, but in the future as well.

After working as a construction manager for several years, graduate engineer Jens-Uwe Lau opened his architectural office in Bonn 10 years ago. The team of ten is able to realise several projects every year, from the design stage to handing it over to private investors and developers. His customers appreciate not only his creative and user-oriented designs, but also his precise preliminary calculation, his fair treatment of the companies involved and his sense for sustainability. And the fact that he is virtually always able to meet the construction time limit, the costs and the high quality standards has to do with his many years of experience, the intense communication with all parties involved and the professional controlling on the part of the respective project managers.

[Translate to english:] Dieser Ruf eilte dem Duo auch im Falle des Hochhauses in Erftstadt voraus und führte schließlich zur Beauftragung zum Entwurf, Planung und der Bauleitung des Neubaus von zwei fast 60 Meter hohen Fassaden, die das Gebäude in Zukunft beschützen sollen.

The office’s reputation also preceded it in the case of the high-rise building in Erftstadt. For these reasons, it was eventually commissioned with the design, the planning and the construction management of the new construction of two façades that are nearly 60 metres high and will protect the building in the future.

Experts are needed when the air gets “thin”

It all began two years ago. In the course of the renovation of the flat roof, it was accidentally discovered that the two 350-ton exposed aggregated concrete façades on the gable sides of the house could not be saved after nearly 45 years. A majority of the supports had loosened, there was imminent danger and the community of owners was forced to immediately have the façades secured with steel nets before they were disassembled step by step. With the help of a special crane, the industrial climbers had to demonstrate their skills as they removed the concrete plates piece by piece before handing them over to the crane hook.

In the right place at the right time

When looking for a sustainable and light alternative solution, it did not take the architect long before he came across the proven PREFA façade systems. And he found a congenial partner in the object consultant Carsten Friedt, who already delivers constructive possible solutions in the planning phase and also serves as a link to the Schröder Bedachungstechnik GmbH from Cologne that was commissioned with the construction.

Project Manager Kristina Prelec remembers: “It was a very complex task. It wasn’t possible to convince the community of owners to choose a solution made of aluminium with a simple sampling. In a case like this, it was a great advantage that PREFA has its own photo service and could provide possible façade and colour variants with photomontages to help the clients in their decision-making process.”

Many solutions instead of many compromises

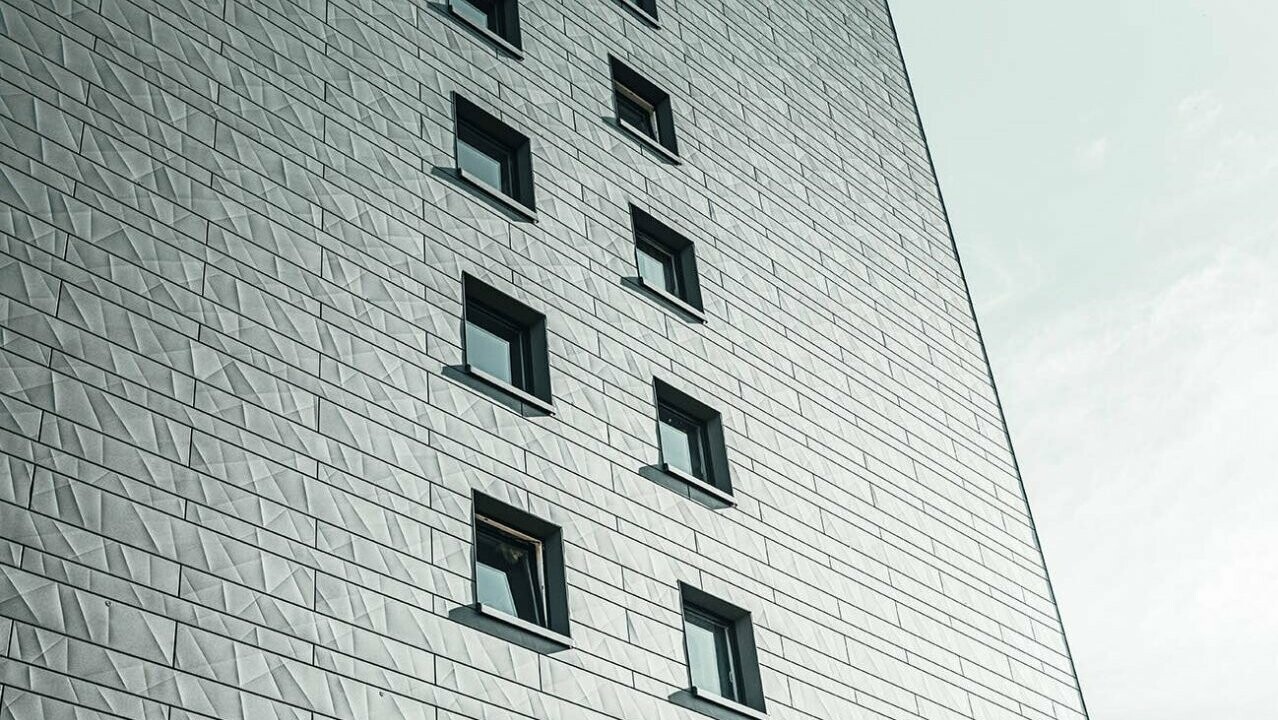

It was eventually decided to use PREFA siding.X with the construction widths of 400 mm, 300 mm and 200 mm in the colour P.10 light grey. The clear installation scheme designed by the architect and the unique, striking longitudinal and transverse edges of the sidings contribute to the modern and timeless appearance of the two 900 m² and 59 metre high gable sides and therefore of the entire building from the 70s. This is topped off by an investment security due to a 40-year colour and material guarantee.

Together with Heribert Paul of the laying company, the expert for statics DI Jörg Friedrich of the engineering office Tragwerk and Carsten Friedt, the architect was able to clarify the feasibility and many other details. “Other laws apply for building heights like these. The wind suction, wind pressure and torsions of the building structure, fire and lightning protection as well as connections to the various different window types were very challenging. Due to the close collaboration between all trades, intelligent custom solutions and the perfect construction management by Dr. André Glaubitt of the engineering office Dipl.-Ing. Franz-Josef Bilo and Prof. Dr.-Ing. Matthias Middel, the new construction of the façades could be completed on time without any significant problems.”

Both Jens-Uwe Lau and Carsten Friedt see great potential regarding sustainable high-rise renovations across borders and hope that this example will set a precedent.

Other laws apply for building heights like these.

A digression for architects and planners

Jens-Uwe Lau draws on the following examples to illustrate the significance of the merger of industry and craft when developing custom solutions:

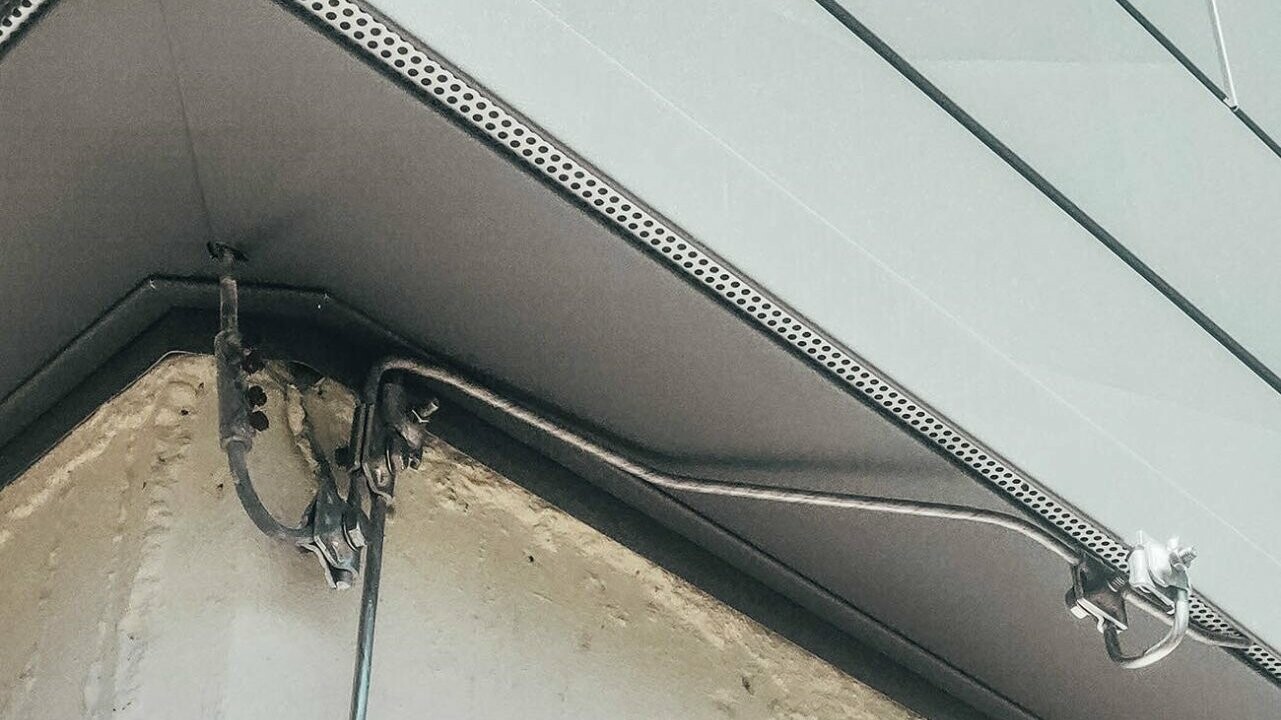

We were able to tackle the subject of wind suction and wind pressure relatively quickly. For a storm-proof assembly in heights of up to 60 metres, the sidings were secured with PREFA storm-proof clips without limiting the “freedom of movement” due to thermal changes or torsions of the building. In order to also withstand the building’s movements unscathed, the substructure was divided accordingly and the sidings were fastened with fixed and gliding points according to the PREFA laying plan.

As a fire safety measure, a fire barrier made of stone wool that was fastened with insulation material plates made of a synthetic material was erected on every second storey. In the event of a fire, the non-flammable supports melt, the stone wool falls down to the sidings and thus prevents the flames and smoke from reaching the upper storeys.

The support profiles of the substructure were included in the lightning protection system. Due to connections of the support profiles that comply with lightning protection, the lightning conductors were connected to the uppermost profiles right underneath the roof parapet. The lightning strike is directly passed down to the earth entry via the aluminium substructure, which means that the façade image is not impaired by external arresters.

When façades are renovated, it is often the case that all of the windows are replaced with new ones and installed in the façade by a tinsmith. In this case, this was not possible, as nearly every storey has differently designed windows that were installed at different times – which will also be the same in the future. The façade had to be connected to the windows in a way so they can also be exchanged from the inside without great effort in years to come.

Skyscraper Erftstadt - details

Country: |

Germany |

Building, location: |

skyscraper, Erftstadt |

Category: |

reconstruction |

Architecture: |

Lau Architektur |

Installer: |

Schröder Bedachungstechnik GmbH |

Material: |

|

Colour: |

P.10 light grey |

Further information

- Text: Carl Bender

- Photos: Kristina Prelec, Jens-Uwe Lau, Martin Croce, Schröder Bedachungstechnik, Carsten Friedt