Projects & inspiration overview References Project configurator Photo montage Construction tips

Products overview Roof Façade Roof drainage Solar Flood protection solutions Coils and metal sheets

Resources overview Project configurator Photo montage Order brochures Request a guarantee certificate Trade fairs Questions and answers Your PREFA contact For installers For architects

Benefits overview Building material aluminium Special topics

Company overview About us Job offers News Press

Contact overview Your PREFA contact Contact form Order brochures

References overview Case studies Architecture Highlights Renovation Gallery

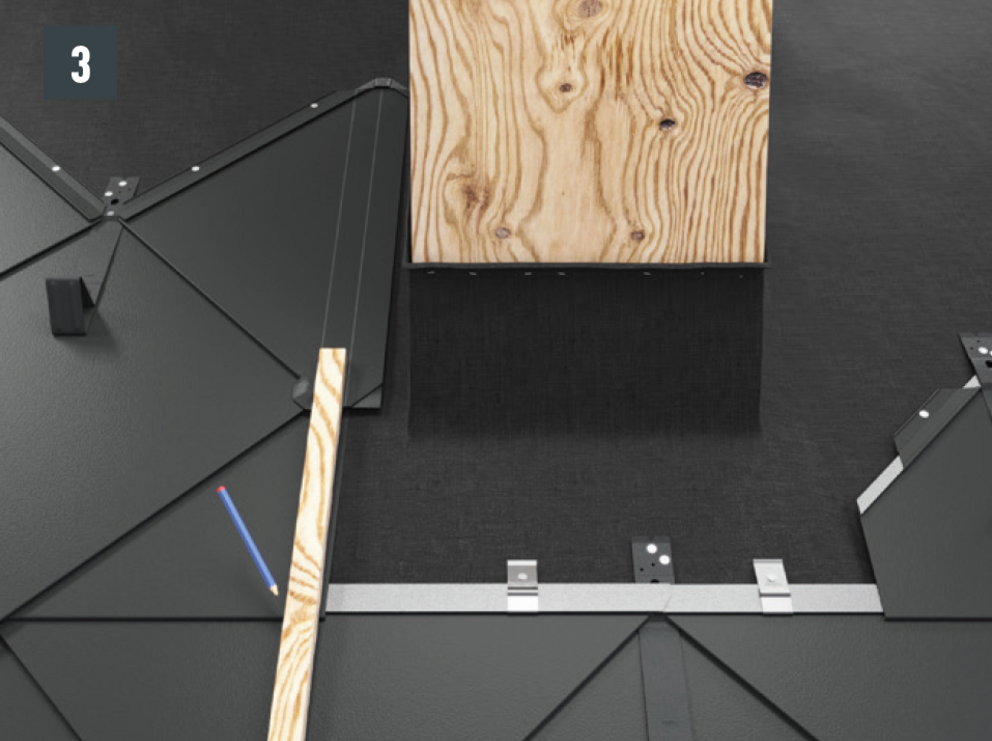

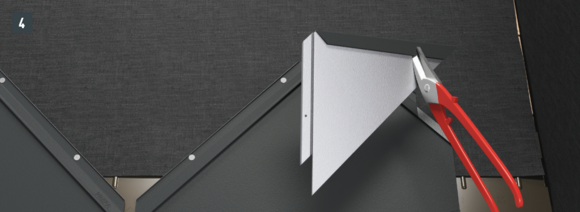

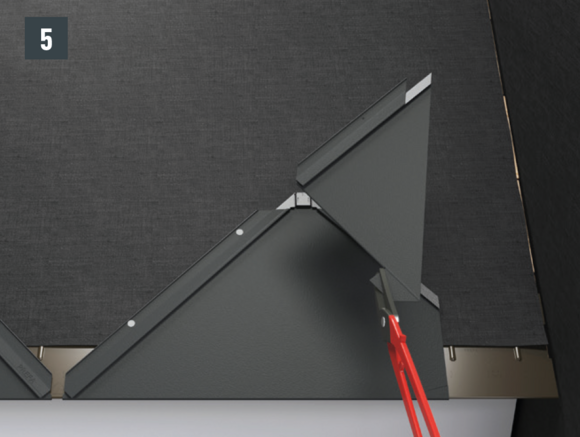

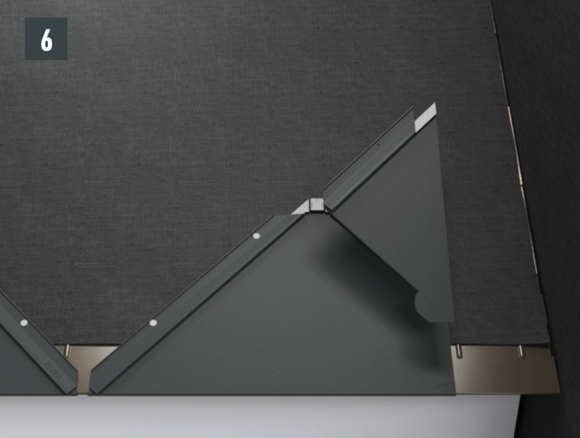

Construction tips overview Roof renovation Facade design Wood & Aluminium Façades Coverings for every roof shape Lightweight metal roof

For installers overview My PREFA Login Academy Installation guidelines & assembly instructions Instruction and demonstration videos Advertising Material, logos & product samples

For architects overview Experience PREFARENZEN Order our architectural brochure and architect folder Download centre BIM

Building material aluminium overview 40-Year guarantee Sustainability Complete System Storm-proof

Special topics overview Fire protection Listed buildings

About us overview Facts and figures Our values and goals Sustainability