Benefits of the extruded profiles

Variety of customised designs

Can be combined and installed in a modular manner (ripple & serrated profiles, horizontal, vertical, diagonal)

High resistance

1.8 mm profiles (vandalism protection in ground floor zones)

Durable, corrosion-resistant, virtually maintenance-free

Variety of colours (powder-coated) or plain aluminium (anodisable)

Easy to install

Same visible widths, low weight

Uniform, high-quality appearance due to concealed fastening

The combination creates exciting visual effects.: Expert tip

Thanks to the uniform visible width and suitable exterior, the different variants of an extruded profile, as well as serrated and ripple profiles on the rainscreen, can be combined in a modular manner – and installed vertically, horizontally or diagonally.

Ideal for balcony cladding

The extruded profiles from PREFA are extremely robust and unbreakable due to their profile thickness of 1.8 mm, allowing even sensitive areas of a building to be clad permanently and durably.

As balcony cladding, the system is impressive in terms of its functional and aesthetic privacy and wind protection. At the same time, it meets the legal requirements for fall-through protection.

You also have free rein when it comes to the colour scheme

Thanks to the colour coordination with the PREFA complete system, an aesthetically sophisticated building shell has been achieved. The ripple and serrated extruded profiles are easy to clean and available in an endless variety of colours:

- in all PREFA P.10 colours

- powder-coated in all available RAL or NCS colours

- plain aluminium (anodisable)

This ensures an attractive appearance and high resistance.

Get inspired by real-life properties that have already been implemented!

A façade made of PREFA extruded profiles is a very robust option to clad the exterior wall. It is irrelevant whether the entire façade or just a section of it is implemented. You will find even more inspiration in our Reference Gallery.

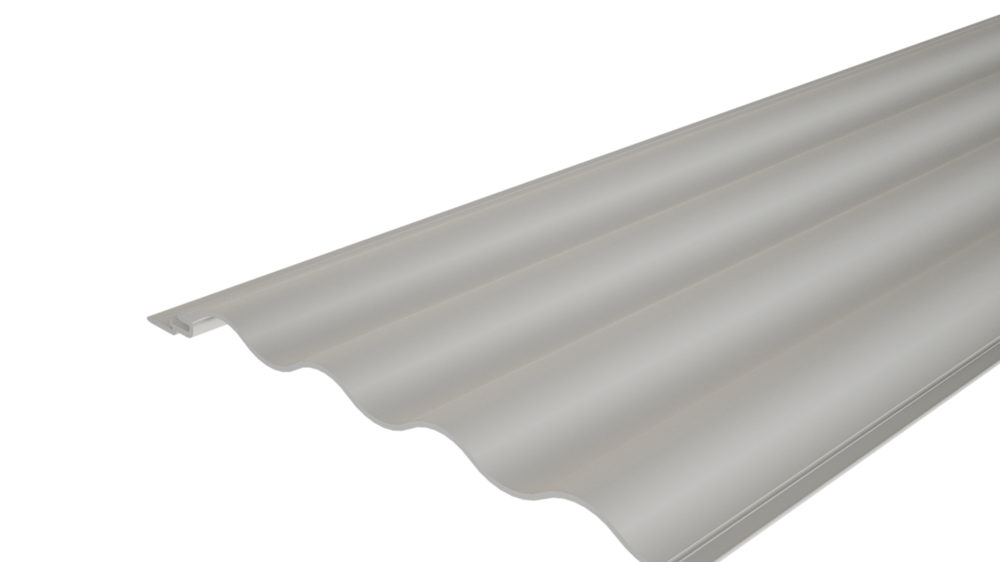

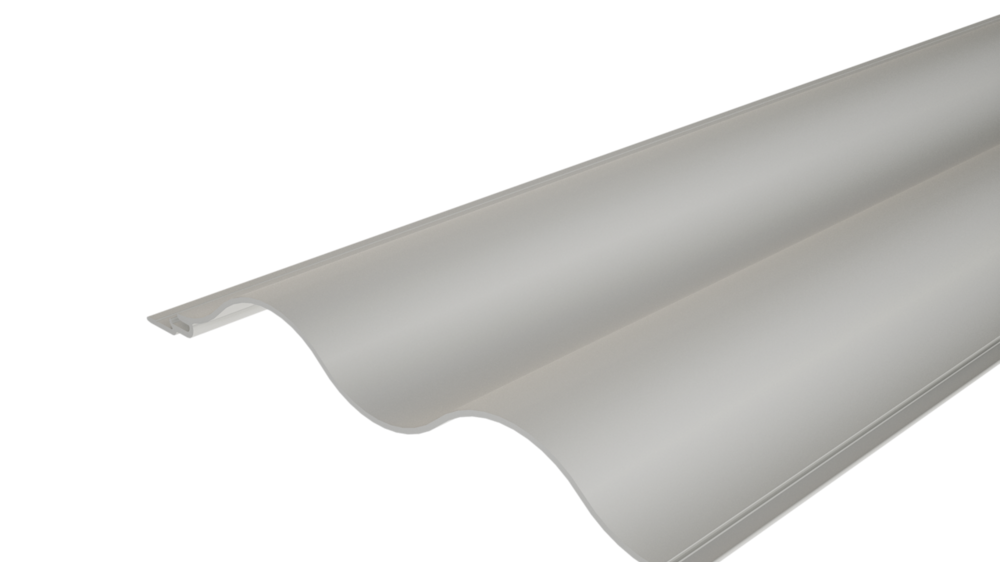

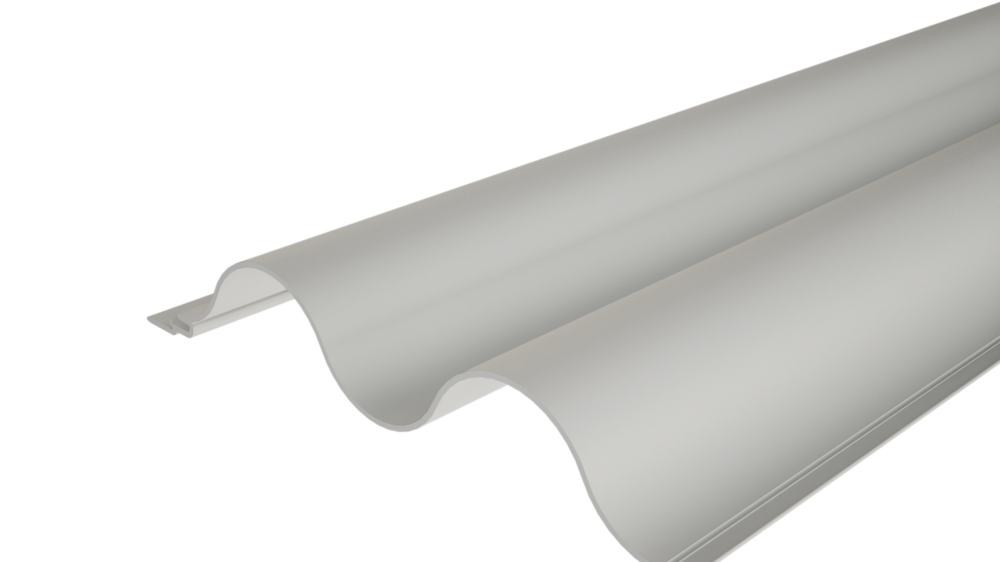

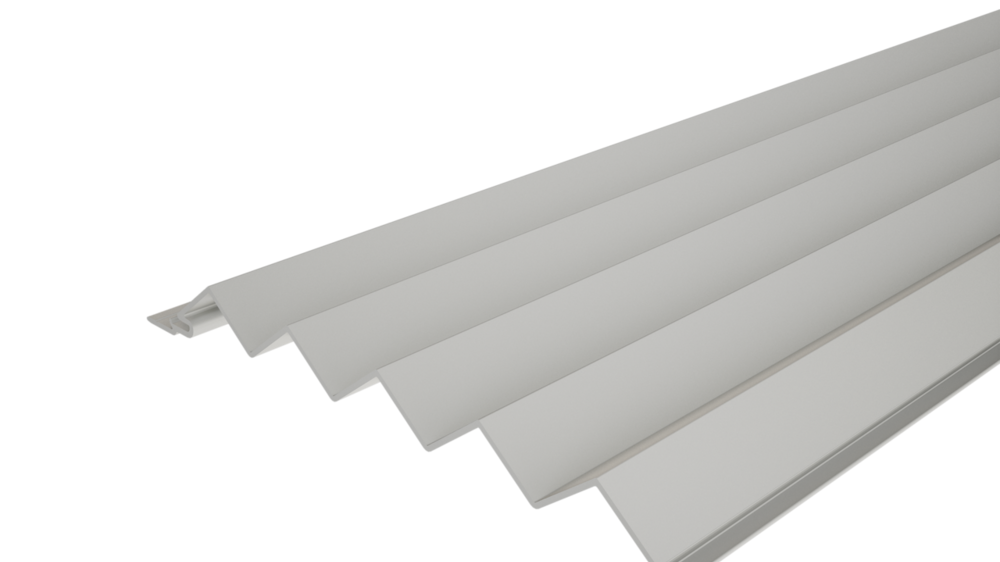

Ripple extruded profile

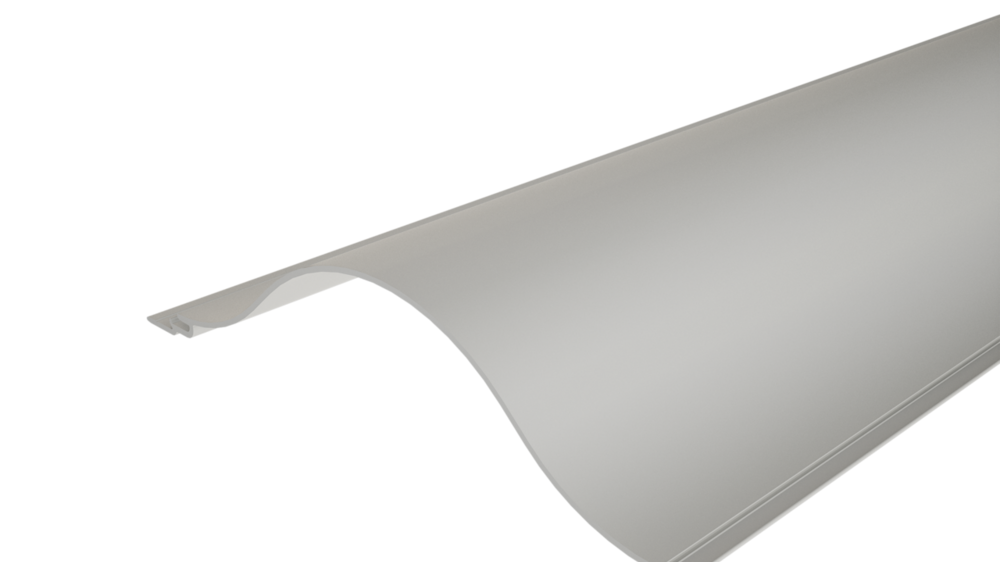

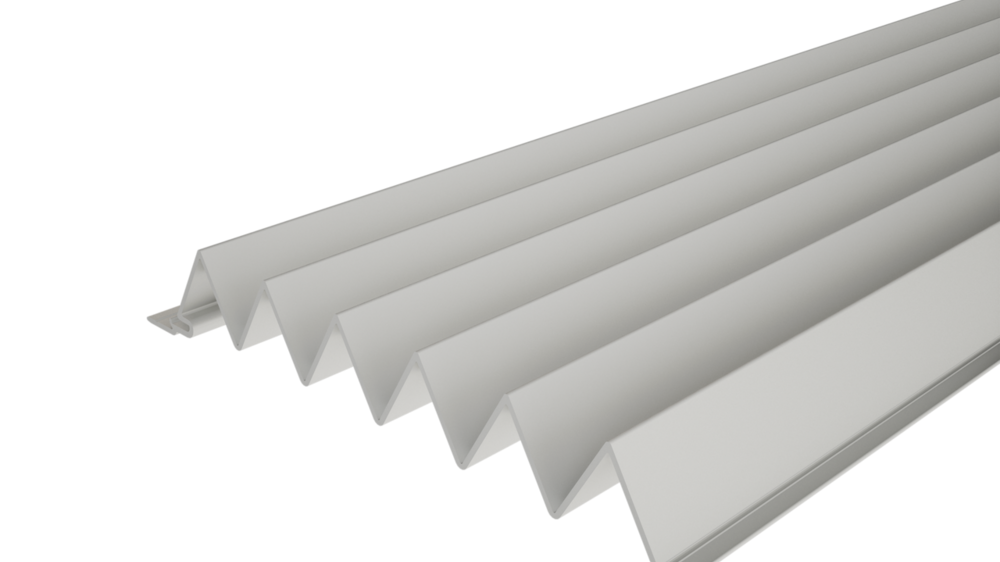

Serrated extruded profile

Do you have questions about the extruded façade?

PREFA façades are installed as non-bearing, rear-ventilated façades. This means that there is a gap for rear ventilation between the aluminium façade cladding and the insulation. In summer, the hot air cannot accumulate behind the façade because it rises through the rear ventilation and is transported away. In the winter, this structure provides thermal protection, as the heat transfer resistance is increased in the rear-ventilated space. This temperature buffering in the rear-ventilated space ensures a comfortable indoor climate all year round.

Fears of rusting are completely unfounded because aluminium cannot rust. If the surface of the PREFA aluminium façade is damaged, a new protective oxide layer is formed and the durability of the PREFA façade remains unchanged.

Non-bearing, rear-ventilated façades are designed to prevent moisture from forming. By separating the insulation and façade cladding, there is a constant air flow in the rear-ventilated space which regulates the moisture balance and ensures dryness. Thanks to the permanent ventilation, professional installation will not result in mould formation underneath the façade.

Technical information

Ripple |

Serrated |

|

Material |

Extruded aluminium with a thickness of 1.8 mm |

Extruded aluminium with a thickness of 1.8 mm |

Dimensions (profile height/spacing/material thickness) |

Ripple 10/50/1,8 mm Ripple 22/100/1,8 mm Ripple 34/100/1,8 mm Ripple 44/200/1,8 mm |

Serrated 18/40/1,8 mm Serrated 29/33/1,8 mm |

Weight |

Ripple 10/50: 6,4 kg/m² Ripple 22/100: 6,6 kg/m² Ripple 34/100: 7,3 kg/m² Ripple 44/200: 6,6 kg/m² |

Serrated 18/40: 7,4 kg/m² Serrated 29/33: 10,5 kg/m² |

visible width |

uniform 200 mm |

uniform 200 mm |

Laying directions |

horizontal, vertical or diagonal |

horizontal, vertical or diagonal |

Fastening |

screwed in a concealed manner with the sliding clip to the aluminium, steel or timber supporting sub-structure according to static requirements |

screwed in a concealed manner with the sliding clip to the aluminium, steel or timber supporting sub-structure according to static requirements |

Lengths |

Uncoated piece lengths: up to max. 6,200 mm Powder-coated piece lengths: up to max. 6,200 mm |

Uncoated piece lengths: up to max. 6,200 mm Powder-coated piece lengths: up to max. 6,200 mm |

Planning & Application

Here, our installers and architects can download specification documents and details about extruded profiles. You can find the installation instructions for extruded profiles in the Service Area. (The service area is only accessible for partner companies – please have your log-in details ready. Not received your log-in details yet? Please contact your Local Sales Manager in that case.)

Special note for our architecture and design studios: 3D and BIM data, as well as textures for our products, can also be found at: digital planning

Technical details

Accessories for extruded profiles

The range of accessories for extruded profiles with starter, junction and corner profiles ensures easy, trouble-free installation. For aesthetically pleasing joints and end pieces, colour-coordinated flashings are available – they give the façade a particularly harmonious surface effect. The system is technically advanced, as it can be installed in such a manner with a sliding clip that it can expand, thus balancing out temperature-induced pressures and deformations.

For a complete, detailed list of accessory products, see our price list or PREFA’s online store (only for processors).