Prefa Material Advantages

As of 2022, Pagano – the luxury brand among prefabricated houses – will equip all its houses with PREFA aluminium as standard. The decision for PREFA was made just recently at the headquarters in Rome, after Andrea Paco and Enzo Pagano convinced themselves of the advantages of the material.

High-quality craftmanship

A Pagano show house near Rimini offered the first opportunity to replace the original roof flashings made of copper with Prefalz in the colour nut brown. The PREFARENZEN team was on site, met the installer and was able to convince itself of the result.

“The fact that we will be working on all new Pagano houses in the future also represents a special logistical challenge for a company of our size,” Elisabetta Spinelli and Jürgen Niederfriniger, who only founded the innovative company Nieder S.r.l. ten years ago, tell us. “The exclusive, individually planned wooden houses, which are produced as a ‘kit’, are built turnkey ready by Pagano assemblers from Italy for wealthy clients across all continents. We are among the few external partners who are even airlifted to the most remote construction sites due to their special handicraft skills.”

The Pagano system

For generations, innovation and intuition have also determined the development of the family-run wood construction company. The unique knowledge of the drying, treatment and processing of wood has been passed on, continuously developed and guarded within the family for more than 120 years.

In the early 1960s, Vincenzo Pagano planned and built a chalet consisting of solid chestnut wood at the present-day company headquarters in Trigoria near Rome. It was followed by halls for the new joinery, show houses for trade fairs and finally the first housing complexes close to nature. At the same time, he was investing in the development of woodworking machines and his employees’ training, and he also brought engineers and architects into his team.

From then on, the design and the production technology were constantly developed, international contacts were made, more than 2000 luxury houses were built across the world and the company was handed over to his two sons Andrea Paco and Enzo Pagano.

Enzo, an architect, is in direct contact with his clients all over the world. He is backed by a multidisciplinary team of more than 50 experts: Architects, planners, specialised technicians, designers, researchers and software experts work in a synergetic and coordinated manner, which makes it possible for them to guarantee top results.

Enzo, what is so special about your houses?

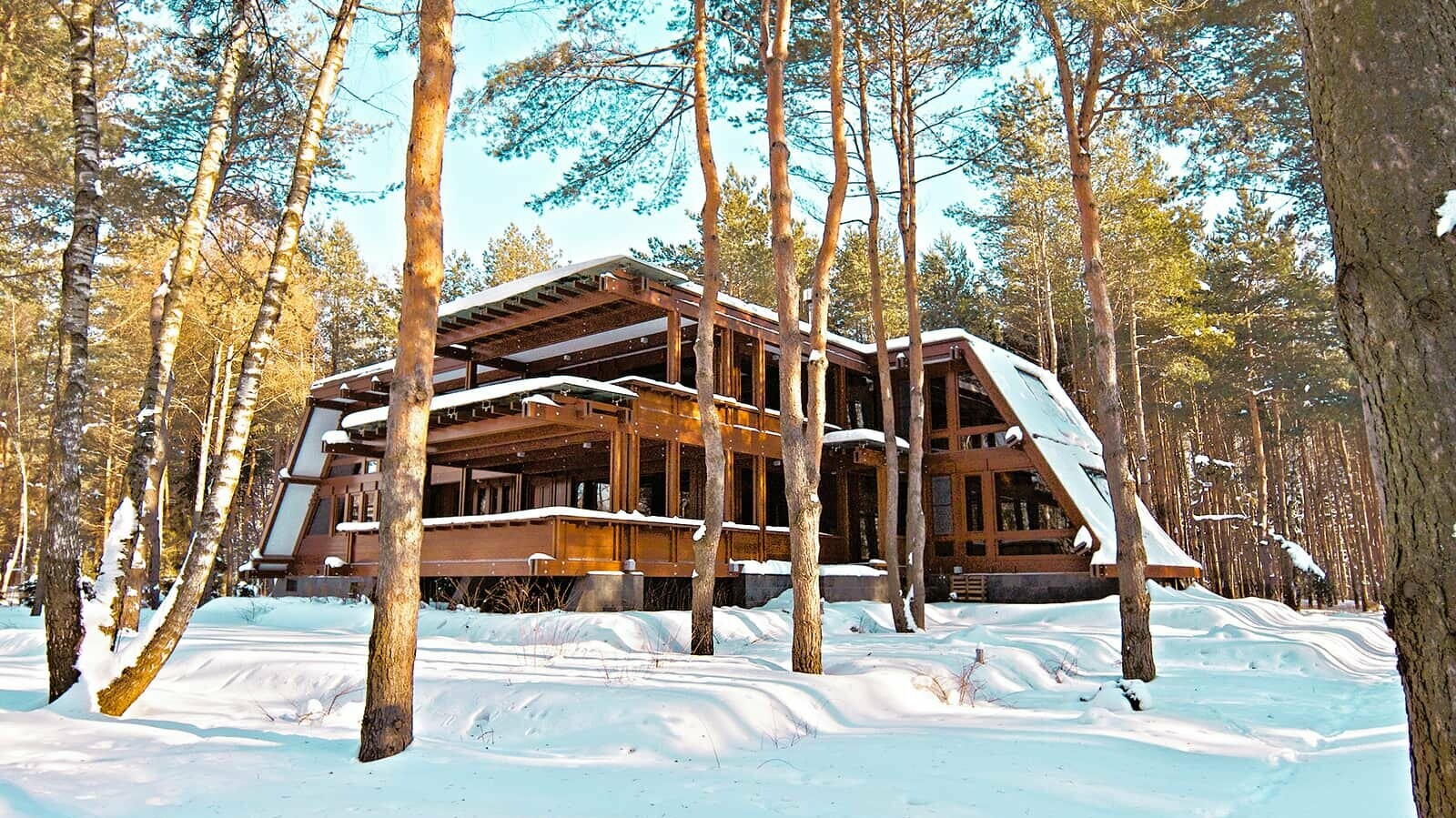

“They are examples of contemporary wood architecture that perfectly integrates itself into the surrounding nature and landscape. Large, movable glass elements enable direct contact with nature, light rooms and a magnificent sense of life. Most of our clients are successful personalities who are used to living a life in luxury. They own large estates in natural areas by lakes, by the sea or in the mountains. These are ideal conditions for our sustainable architectural concept, which places the relationship between interior and exterior spaces at its centre.

With the help of digital planning and high-grade visualisations, we are able to include such clients in the process from the beginning and therefore react to their ideas and wishes. Especially with houses that have living areas of 1000 to 2500 m², this is a great advantage for everyone involved.

The structure of the constructions is based on patented systems as well as the digital planning of all details. We prepare the internal framework made of fir wood at our factory and finish the surfaces with panels consisting of valuable Iroko wood. In the outside area, we only use Iroko, which guarantees durability for centuries. Parallel to this, we produce the ceiling and wall elements including the installations and the final surfaces.

The fact that not only the structure is built at our factory results in a consistently high quality and construction times of around one fifth compared to other construction projects. Moreover, our clients have the possibility to see the progress of each construction phase and discuss alterations with experts on site. On average, we can design a 500 m² large house in about three months, produce it in four months and assemble it in one month.”

Why PREFA aluminium instead of copper?

“PREFA aluminium is a high-quality, sustainable product that can be ideally combined with the materials in our houses. Compared to copper, the many products and colours make it possible for us to better tailor our houses to the respective locations, and we can also increase the contrasts between the elements more successfully with this material.

With Jürgen Niederfriniger and his company, we not only have a conscientious tinsmith who could convince us of the quality and advantages of PREFA, but we have also found an ideal partner whose drive to find innovative, creative solutions and executions that are also high-quality in terms of craftmanship is a perfect fit for Pagano. We are currently expanding our cooperation to all projects in Italy and abroad and are also thinking about including Nieder in the further development of our modular systems.”

Further information

- Text & Interview: Carl Bender

- Photos: © Croce & Wir, © Pagano