Overall Information

- Primary aluminium Aluminium is obtained from bauxite, an aluminium ore named after Les Baux – the place where it was discovered. Bauxit usually consists of up to 60% alumina, iron oxide and silica. It is mainly found in South America, Australia and Africa.

- Secondary aluminium Secondary aluminium consists of recycled aluminium and is recovered from scrap metal recycling. During preparation, only 5% of the extraction energy used to produce primary aluminium is used.

Find more information about television aerials on the Electromagnetic interference page.

Roof

Metal roofs can be integrated into the exterior lightning protection system in accordance with the standard ÖVE/ÖNORM EN 62305-3. PREFA flat band roof panels (Prefalz and Falzonal) are therefore permitted as a natural part of the arrester and PREFA small format components (roof tiles, shingle, roof panels, rhomboid roof tiles) as natural components of the conductor (installation of an additional arrester and connection to the earth). Some standards stipulate exceptions according to which, for example, property at increased risk (e.g. potentially explosive premises) must be specially designed. The integration of PREFA roof and façade systems in the exterior lightning protection system must therefore be planned depending on the specifics of property in question. Information on the necessity and type of lightning protection on a property can be obtained from a lightning protection system engineer or approved electrician. Find out more about lightning protection here.

Due to the increasing number of mobile phone users, questions about electromagnetic shielding to protect against the emanating radiation are increasingly being asked. As each radio communication is transmitted between sending and receiving devices, the number of transmission masts being erected in populated areas is growing.

It would be great if we could give you an overall price here or tell you that a roof tile or façade single costs such and such an amount. Unfortunately, it’s not that simple because each PREFA roof and façade needs to be carefully calculated by a specialist installer. Our professional roofers will give you an individual quote, tailored precisely to your requirements and the local conditions in which your house is located.

The roof and façade are parts of a building that are placed under particular strain by the weather. Sun, wind, rain and snow, as well as constant moisture (in wooded or shaded locations), have an impact on the building shell. Dirt deposits (e.g. dust, foliage or pine needles) can impair the function and the appearance of the roof, the façade or the roof drainage (e.g. blockage). It is therefore advisable to check roofs, façade cladding and roof drainage systems (gutters and downpipes) at regular intervals. This way, any emerging changes, damage or dirt can be identified and remedied in good time. You can find more information on cleaning and maintenance here.

Façade

PREFA products cannot be purchased and assembled by end users themselves, as they are not suitable for self-installation. They are available exclusively through our trained specialist companies who also perform the proper installation. Our material and colour guarantee can only be used if the product has been installed by one of our partner companies.

PREFA is not a rendered façade. It is a high-quality aluminium façade which is installed as a non-bearing, rear-ventilated façade.

Fears of rusting are completely unfounded because aluminium cannot rust. If the surface of the PREFA aluminium façade is damaged, a new protective oxide layer is formed and the durability of the PREFA façade remains unchanged.

PREFA façades are installed as non-bearing, rear-ventilated façades. This means that there is a gap for rear ventilation between the aluminium façade cladding and the insulation. In summer, the hot air cannot accumulate behind the façade because it rises through the rear ventilation and is transported away. In the winter, this structure provides thermal protection, as the heat transfer resistance is increased in the rear-ventilated space. This temperature buffering in the rear-ventilated space ensures a comfortable indoor climate all year round.

The PREFA façade is the outermost protective layer of your house and simultaneously serves as a visual design element to improve the look of your home. Not only is it nice to look at, it also protects your home from the weather. In addition, durable PREFA aluminium cladding protects the underlying layers (supporting structure, insulation and substructure) from the effects of the weather. Owing to the fact that your PREFA façade is particularly weather-resistant, you can enjoy its beautiful appearance for decades.

It should be noted that PREFA façade products must not be confused with sandwich panels or other products with integrated insulation, as they are exclusively specialised for the functions mentioned above (protection and visual design). If you would also like to have a high-quality aluminium PREFA façade, the skilled workshop will be able to provide you with a suitable substructure and, if desired, suitable insulation in addition to improving the appearance of your home with PREFA façade cladding.

Non-bearing, rear-ventilated façades are designed to prevent moisture from forming. By separating the insulation and façade cladding, there is a constant air flow in the rear-ventilated space which regulates the moisture balance and ensures dryness. Thanks to the permanent ventilation, professional installation will not result in mould formation underneath the façade.

If the PREFA façade is installed properly, a perforated plate or ventilation grid will be installed at the ventilation inlet and outlet which protects against animals. As long as it is installed properly, small animals such as birds or mice will therefore be unable to damage your façade.

PREFA products are exclusively available through our trained, independent ‘partner companies’, who also perform the installation. This way, we can ensure that our products are installed properly. We offer regular training sessions for our tradesmen at the PREFA Academy, as we want to ensure that our products are handled with consistent quality.

Aluminium can be recycled 100% without loss of quality. In the recycling process, only 5% of the original manufacturing energy is required. PREFA largely uses recycled aluminium, which is also referred to as secondary aluminium. Therefore, aluminium is also an ideal material from an ecological point of view.

PREFA offers a 40-year colour and material guarantee on its products with the exceptional P.10 surface against breaking, corrosion (rust), frost damage, chipping and blistering.

PREFA does not supply PE cores in its aluminium composite panels. It uses high-quality FR cores. FR stands for ‘fire-retardant’ (reaction to fire classification according to EN 13501-1 ‘B-s1, d0’). In addition, PREFA aluminium composite panels are also supplied with a non-flammable A2 core. Details on the fire classification of PREFA façades can be found in the PREFA information sheet on fire protection.

All PREFA aluminium façade systems are produced as rainscreens. A system that has stood the test of time for over a century, and also has a positive impact on the indoor climate thanks to its special structure. Air is allowed to circulate between the masonry and the PREFA façade, wicking away any occasional moisture behind the metal façade.

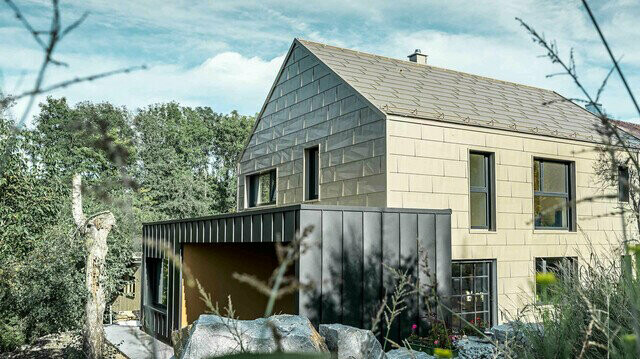

A PREFA façade can be individually adapted due to the variety of designs in terms of colour and shape. The façade systems are designed as a durable rainscreen, which has a positive impact on the indoor climate. In addition, façades with coordinated PREFA roof systems can be designed as an all-in-one system.

Flood protection

PREFA’s mobile flood protection in the aluminium barrier panel system is used to protect buildings and land. It is a reliable water and mud barrier even in extreme situations – from the Danube to the North Sea. Lightweight, robust and easy to assemble, aluminium barrier panels are stacked on top of each other in a tongue and groove system and inserted between two fastening profiles or uprights – in an emergency, they can even be installed by just one person.

The length is determined according to structural calculations and depends on the water level.

A flood protection system does not have to be 100% watertight. Minimal water ingress is acceptable. With the PREFA system, the aluminium profiles are stacked on top of each other in a tongue and groove system and inserted into fastening profiles or uprights on both sides.